Factory making Sinter Filter - Filter disc – FLD Filter

Short Description:

Product Detail

Related Video

Feedback (2)

Factory making Sinter Filter - Filter disc – FLD Filter Detail:

Filter discs are made by special mould via punching process, the raw materials are stainless steel wire mesh, black wire cloth and other rare metal products. Generally used in petroleum, chemical, pharmaceutical, chemical factory.

Shapes: rectangle, square, round, other shapes

Structure: Single layer, double layers and multiple layers.

Material for discs: Stainless fiber sintered felt, stainless steel woven mesh, phosphor mesh, brass mesh, etc. Material for the rim: Al, SS, Copper nickel, etc. Media: single layer or multiple layers. Shapes: round, rectangular, waist, oval, etc.

Application:

Mainly used for the filtration of impurities in polyester film and fiber spinning. Rectangular, square, round, oval, circular, rectangular, cap, waist, other shapes.

Structure: single layer, double layers and multiple layers.

Craft: Spot welding on double layers or three layer products, generally with 4-10 welded points. Also available to do as customer requested.

Material: stainless steel wire mesh, galvanized wire mesh, copper mesh, dutch weave wire mesh, perforated mesh, etc.

Rimmed material: stainless steel plate, copper plate, galvanized plate, aluminum plate, rubber, etc.

Diameter: generally 5–600 mm. Filter disc and filter mesh assembly products (referred to as filter), mainly used in rubber, plastics industry, grain and oil sieving, oil, oil refining, chemical, light industry, medicine, metallurgy, machinery, shipbuilding, automobile and filtration process for tractor industry in distillation, absorption, evaporation, eliminate entrained in the steam or the droplets in the gas and liquid foam, and air cleaner used in the car.

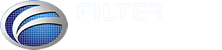

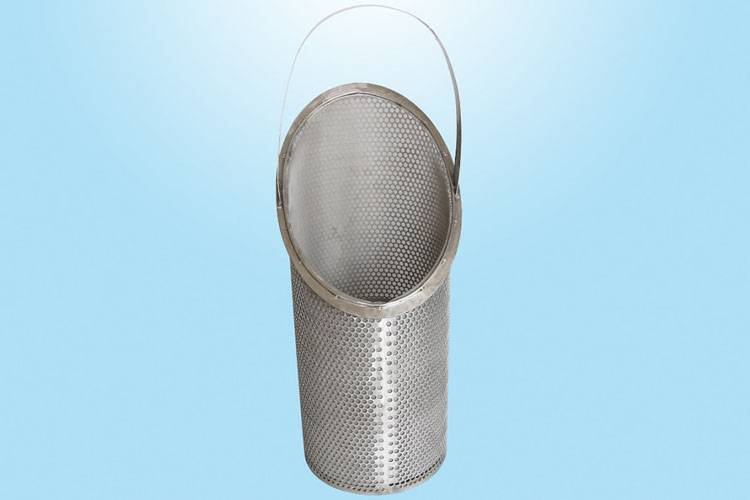

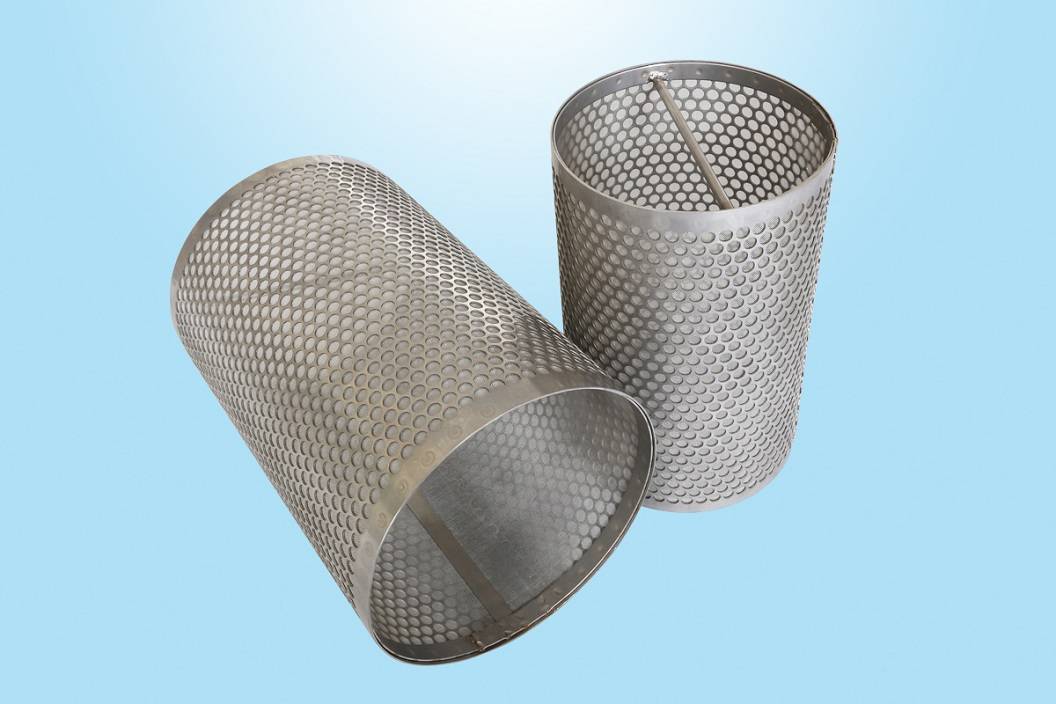

Product detail pictures:

Related Product Guide:

The saga of Demoulas’ Market Basket | Automatic Filter

Firefox New Tab Adult Content Filter Discovered | News & Opinion | Automatic Filter

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Factory making Sinter Filter - Filter disc – FLD Filter, The product will supply to all over the world, such as: Egypt, Bolivia, Uzbekistan, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.