High definition Rimmed Melt Filtration - Filter disc – FLD Filter

Short Description:

Product Detail

Related Video

Feedback (2)

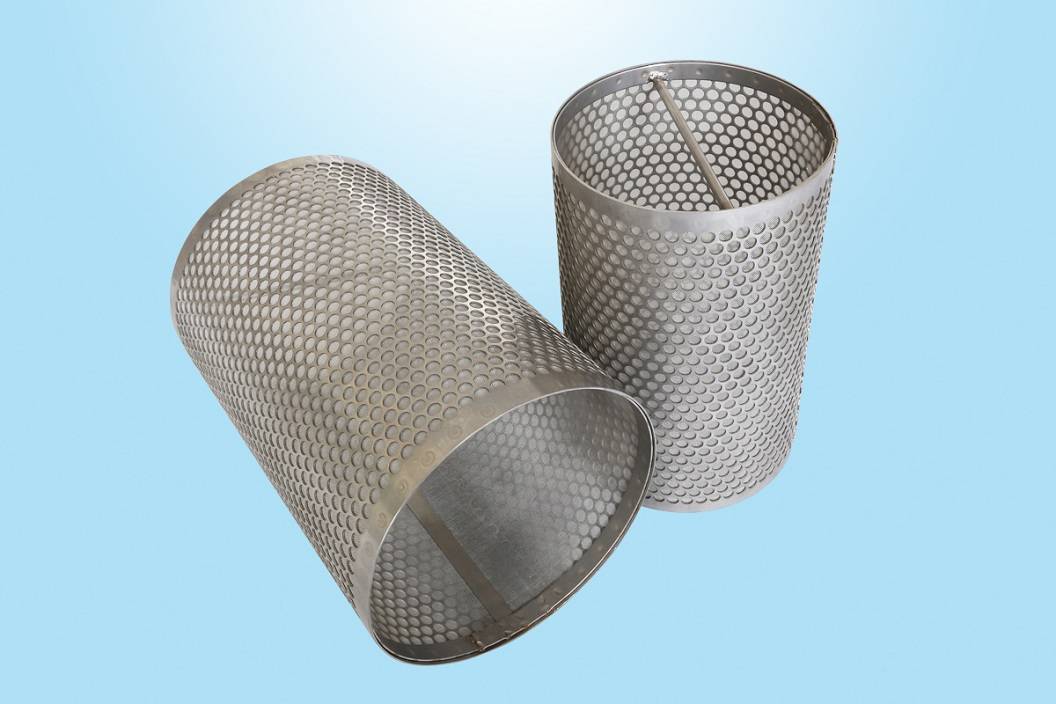

High definition Rimmed Melt Filtration - Filter disc – FLD Filter Detail:

Filter discs are made by special mould via punching process, the raw materials are stainless steel wire mesh, black wire cloth and other rare metal products. Generally used in petroleum, chemical, pharmaceutical, chemical factory.

Shapes: rectangle, square, round, other shapes

Structure: Single layer, double layers and multiple layers.

Material for discs: Stainless fiber sintered felt, stainless steel woven mesh, phosphor mesh, brass mesh, etc. Material for the rim: Al, SS, Copper nickel, etc. Media: single layer or multiple layers. Shapes: round, rectangular, waist, oval, etc.

Application:

Mainly used for the filtration of impurities in polyester film and fiber spinning. Rectangular, square, round, oval, circular, rectangular, cap, waist, other shapes.

Structure: single layer, double layers and multiple layers.

Craft: Spot welding on double layers or three layer products, generally with 4-10 welded points. Also available to do as customer requested.

Material: stainless steel wire mesh, galvanized wire mesh, copper mesh, dutch weave wire mesh, perforated mesh, etc.

Rimmed material: stainless steel plate, copper plate, galvanized plate, aluminum plate, rubber, etc.

Diameter: generally 5–600 mm. Filter disc and filter mesh assembly products (referred to as filter), mainly used in rubber, plastics industry, grain and oil sieving, oil, oil refining, chemical, light industry, medicine, metallurgy, machinery, shipbuilding, automobile and filtration process for tractor industry in distillation, absorption, evaporation, eliminate entrained in the steam or the droplets in the gas and liquid foam, and air cleaner used in the car.

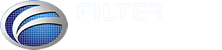

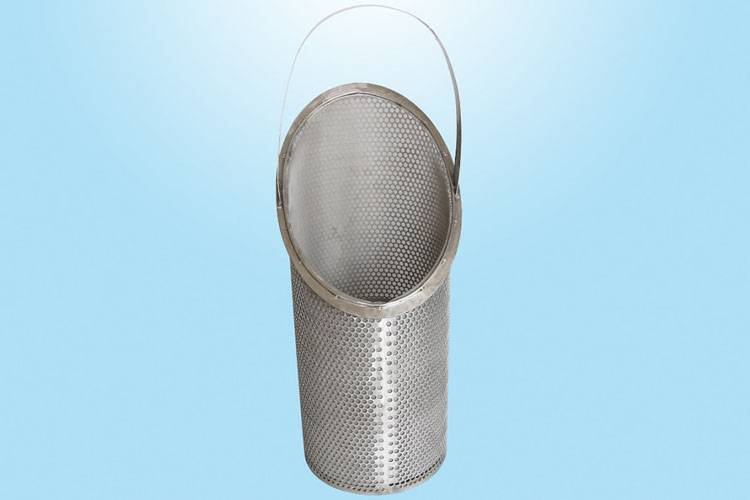

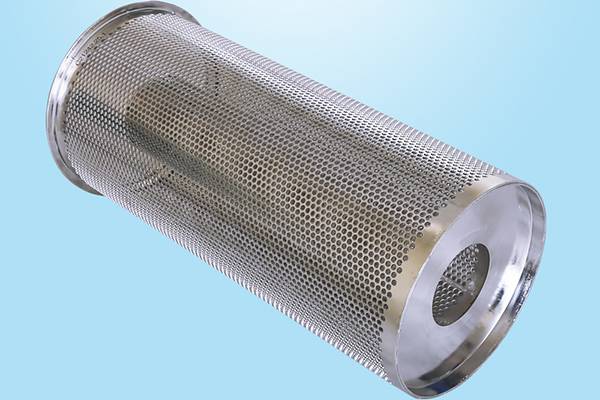

Product detail pictures:

Related Product Guide:

Global Hollow Fiber Ceramic Membrane Market Regional Landscape, Production, Sales & Consumption Status and Prospects 2019-2024 | Fiber Filtration

Using bacteria to create a water filter that kills bacteria | Sea Water Filter

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for High definition Rimmed Melt Filtration - Filter disc – FLD Filter, The product will supply to all over the world, such as: Thailand, Peru, moldova, Should any of these items be of interest to you, please let us know. We'll be satisfied to give you a quotation upon receipt of one's detailed specifications. We have our personal experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.